Kaizen via PlanDoCheckAct PDCA Lean Six Sigma Belgium

The Deming Cycle, also known as the PDCA (Plan-do-check-act) circle is one of the oldest models in the manufacturing world. It was a model that encourages continuous improvement and was first introduced to the world by W. Edwards Deming way back in the 1950s.

PDCA/PDSA

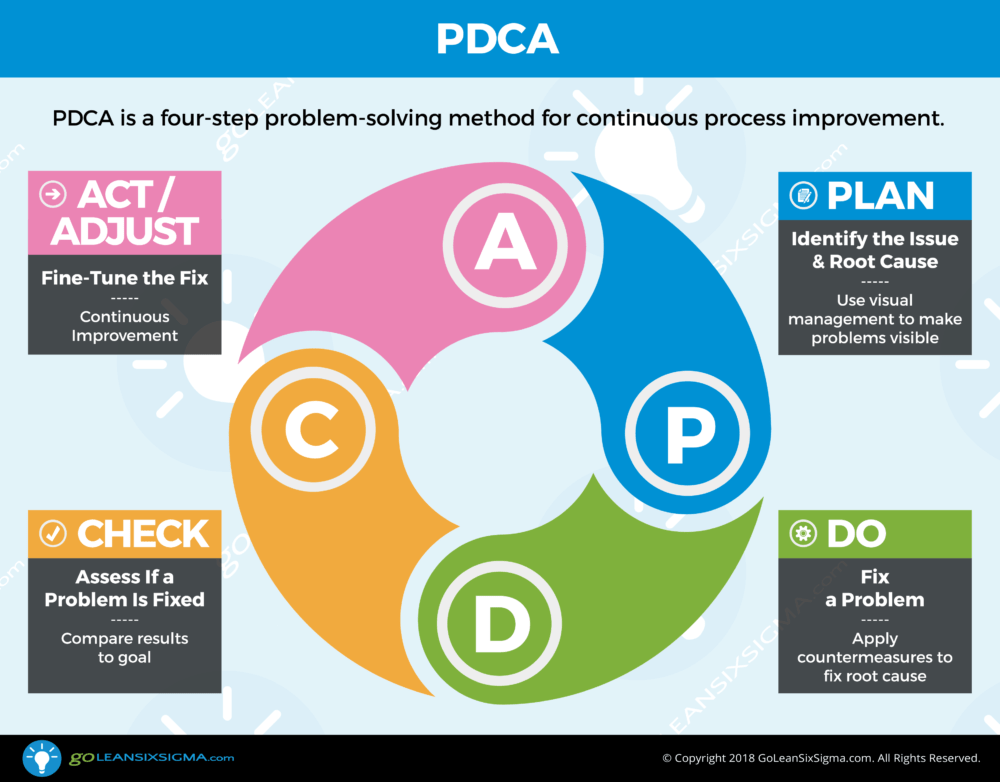

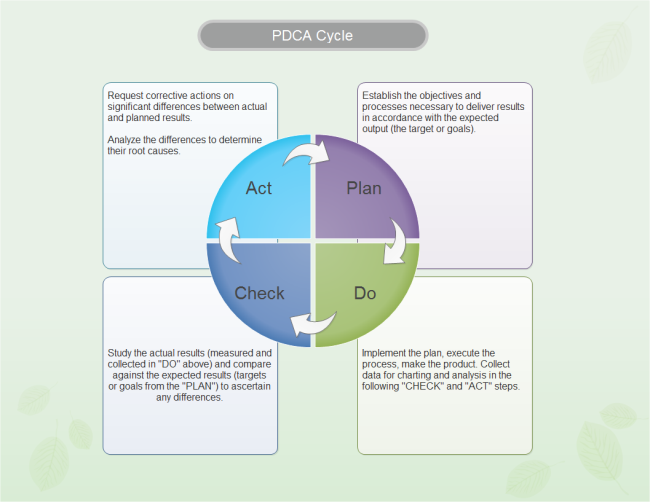

A PDCA Cycle is a Six Sigma quality improvement methodology that consists of four key steps: Plan, Do, Check, and Act. PDCA aims to improve processes by identifying potential problems and implementing solutions continuously. There are four steps in the cycle: Plan: The first step in the PDCA Cycle is to develop a plan for process improvement.

Plan Do Check Act (PDCA) Six Sigma

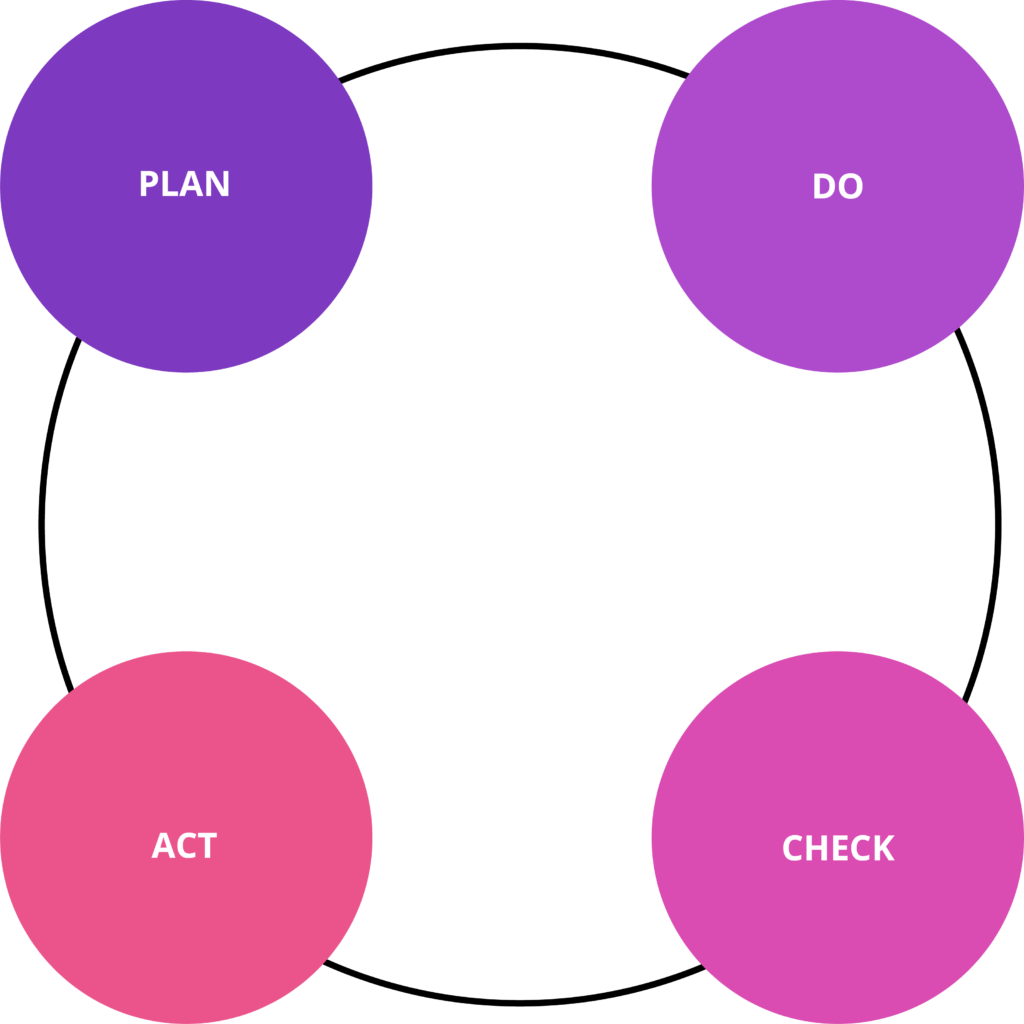

PDCA cycle is one of the simplest and the easiest management approaches for process control and continuous improvement. PDCA - stands for Plan - Do - Check - Act. It is also called Deming's cycle or Shewhart cycle. Sometimes it is also called a PDSA cycle: Plan-do-Study-Act.

Pdca X Six Sigma Substitutos Ou Complementares

The PDCA Cycle is a methodical approach used in continuous improvement businesses. PDCA stands for the steps in the method, which are Plan, Do, Check and Act (sometimes called Adjust). The PDCA cycle was originally developed by A. Shewhart who was a statistician at Bell Telephone Laboratories.

Pdca Plan Do Check Act Pdca Cycle Deming Cycle Pdca Lean Six Sigma Pdca

What is PDCA? The PDCA cycle, also known as the Shewhart cycle, is a management tool that structures thinking into four phases, which are: Plan, Do, Control, and Act. The image below shows how the PDCA cycle can have the activities defined in each stage: To continuously improve production processes, you can apply the PDCA cycle to solve problems.

Six Sigma ou PDCA qual usar? Entenda as diferenças agora! YouTube

The Plan-Do-Check-Act (PDCA) Cycle or Plan-Do-Study-Act (PDSA) Cycle is an iterative four-step problem-solving technique used to improve business processes continuously. This technique maintains a continuous feedback loop, allowing change leaders to formulate and test change theories.

PDCA_DMAIC_A3_8D Lean six sigma, Change management, Problem solving

Find, Organize, Clarify, Understand, Select (FOCUS - PDCA) Published: November 7, 2018 by Ken Feldman. PDCA (Plan-Do-Check-Act) is a popular iterative methodology to fix a problem or improve a process. Developed and promoted by Drs. Deming and Shewhart, it's used as a cycle of examining a problem, collecting some data, improving the process.

FRACAS and Corrective Action CAPA Software per 8D, DMAIC, & PDCA

PDCA (Plan, Do, Check, Act) is a time-tested methodology that forms the backbone of continuous improvement in various industries. The PDCA cycle, which embraces simplicity and systematic progression, facilitates problem-solving and process improvement by following four distinct stages.

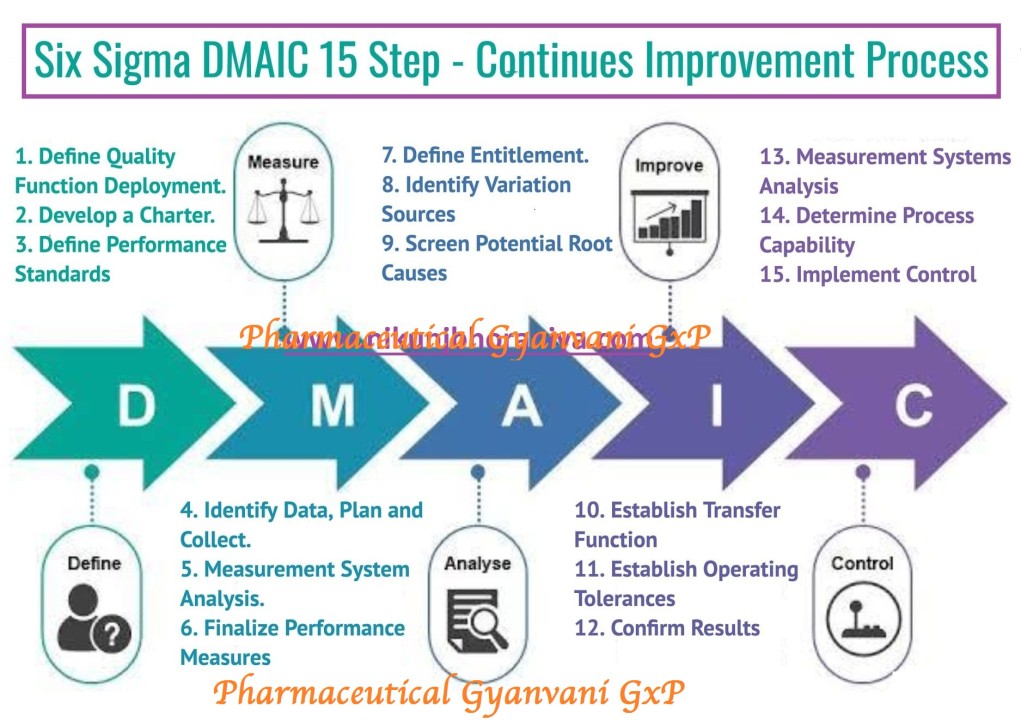

Dmaic Text, Process, Lean Manufacturing, Management, Pdca, Continual

PDCA is an improvement cycle based on the scientific method of proposing a change in a process, implementing the change, measuring the results, and taking appropriate action. It also is known as the Deming Cycle or Deming Wheel after W. Edwards Deming, who introduced the concept in Japan in the 1950s.

PDCA The Lean Six Sigma Company

PDCA Cycle: A four-step problem-solving iterative technique used to improve business processes. The four steps are plan-do-check-act. The PDCA Cycle can be used to effect both major performance.

DMAIC, PDCA, Lean 6 Sigma

Modified and popularized the Shewart cycle (PDCA) to what is now referred to as the "Statistical Method From the Viewpoint Deming Cycle (Plan, Do, Study, of Quality Control" Key Figures in PDCA Act). Plan Tools: Direct observation of process

InDepth Definition of the PDCA Cycle

His approach was a three-step linear problem-solving method. Dr. W. Edwards Deming, the famous quality-control pioneer popularized the technique in the 1950s and took Shewhart's linear three-step process and revised it to be the iterative four-step cycle he called Plan, Do, Check, Act (PDCA). In 1986, Deming revised the description of PDCA.

Pdca Six Sigma

PDCA (plan-do-check-act) cycle, which is also known as Deming Cycle, is a continuous quality improvement model proposed by W. Edwards Deming in the 1950's. He recommended that business processes need to be placed in a continuous feedback loop so that managers can identify and fix the parts of the process that need improvements.

Παράδοση Συντηρητικό Φανταχτερός pdca tools

Six Sigma Terms PDCA (Plan-Do-Check-Act) Dr. W. Edwards Deming used a four step process, which is more of a cycle - - PLAN, DO, CHECK, ACT for process improvement. The idea in the PLAN step is to define the process to improve. The DO step is implementing the plan and measuring its performance.

SOLUTION Tqm Pdca And Six Sigma Studypool

PDCA stands for Plan-Do-Check-Act - a four-stage problem-solving model that enables organizations to continually improve processes, products or services.. It's particularly helpful for implementing Total Quality Management or Six Sigma initiatives, and for improving business processes generally. However, going through the PDCA/PDSA cycle.

"Integrating the PDCA Cycle and Six Sigma for Continuous Improvement"

Glossary PDCA PDCA Abbreviation for Plan Do Check Act, which is a model that provides a framework for the improvement of a process or system. It can be used to monitor a single issues or guide an entire improvement project or initiative.